Adani Cement and Coolbrook to deploy world’s first commercial RotoDynamic Heater

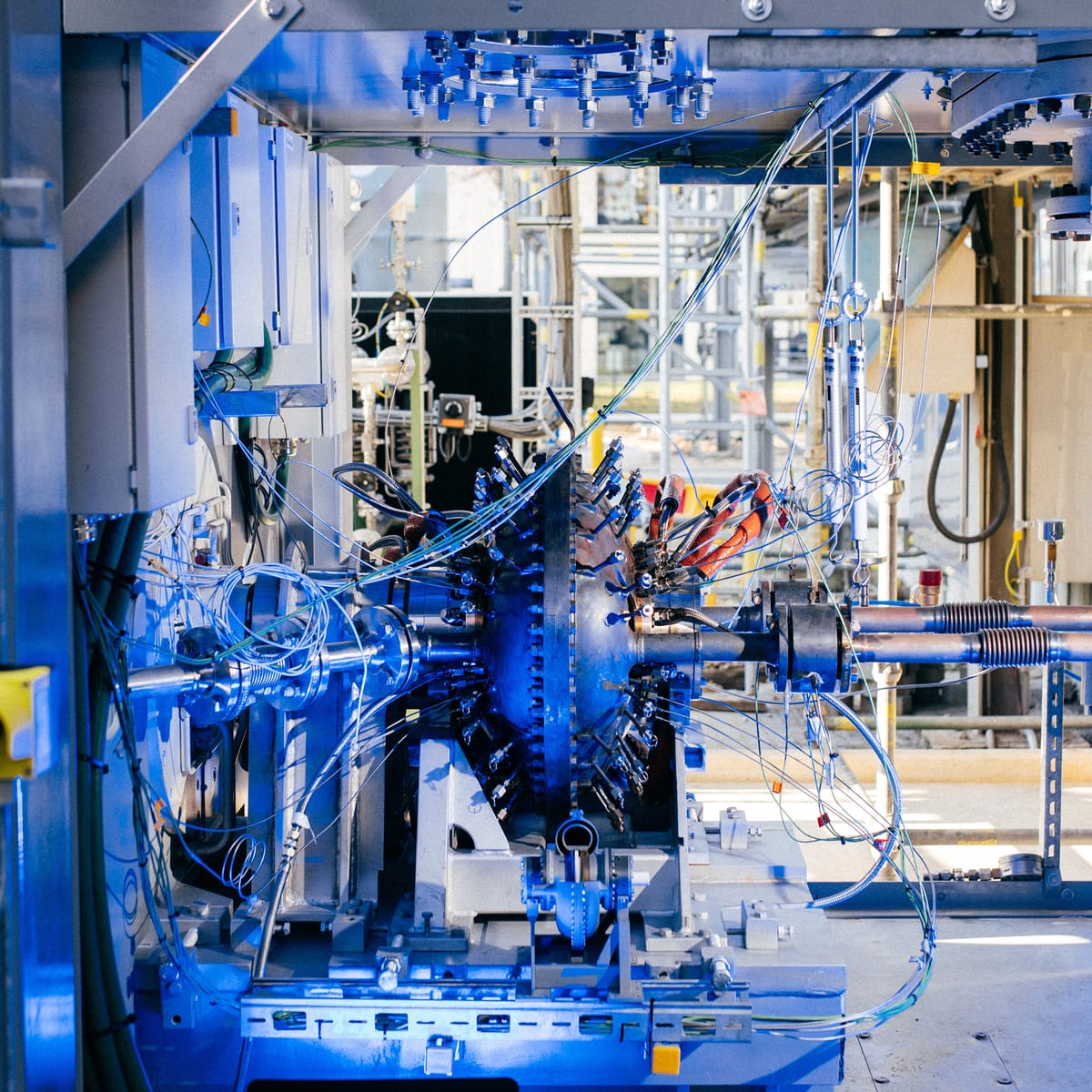

Adani Cement and Coolbrook announce their delivery agreement for the world’s first commercial deployment of the revolutionary RotoDynamic Heater™ (RDH™) technology to advance cement decarbonisation at the Boyareddypalli Integrated Cement Plant in Andhra Pradesh, India. This marks the first industrial scale deployment of Coolbrook’s RDH™ technology, advancing Adani Cement’s net-zero goals achievement by 2050 (validated by the SBTi) and Coolbrook’s goal of cutting 2.4 billion tonnes of annual CO₂ across heavy industry sectors globally.

This technology will decarbonise the calcination phase - the most fossil fuel-intensive stage of cement production. By providing clean heat to dry and enhance the heating value of alternative fuels, the technology enables a significantly higher substitution of fossil fuels with sustainable alternatives. This deployment is expected to directly reduce ~60,000 tonnes of carbon emissions annually with a potential to increase 10x in due course, marking a major step toward decarbonising cement manufacturing.

Critically, the RDH™ system will be powered entirely by Adani Cement’s large-scale renewable energy portfolio, ensuring that the industrial heat generated is completely emission free. This deployment demonstrates the real-world feasibility of clean, electrified industrial heat powered entirely by renewables. This positions Adani Cement to spearhead India’s emergence as the world’s clean manufacturing cement hub.

“Entering into the first industrial-scale project in the world with Adani Cement marks a transformative step for industrial electrification in one of the world’s most vital cement markets,” said Mr Joonas Rauramo, CEO of Coolbrook. “Our mission is to make RotoDynamic Technology a new industry standard for decarbonising hard-to-abate sectors. Together, we’re redefining how cement is produced - cleaner, more efficient, and ready for a net-zero future.”